Heat treatment

It is a method used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material.

Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering and quenching.

Tempering

Untempered martensitic steel, while very hard, is too brittle to be useful for most applications. A method for alleviating this problem is called tempering. Most applications require that quenched parts be tempered. Tempering consists of heating a steel below the lower critical temperature, (often from 400 to 1105 ˚F or 205 to 595 ˚C, depending on the desired results), to impart some toughness. Higher tempering temperatures, (may be up to 1,300 ˚F or 700 ˚C, depending on the alloy and application), are sometimes used to impart further ductility, although some yield strengths is lost.

Stress relieving

Stress relieving is a technique to remove or reduce the internal stresses created in a metal. These stresses may be caused in a number of ways, ranging from cold working to non-uniform cooling. Stress relieving is usually accomplished by heating a metal below the lower critical temperature and then cooling uniformly.

Quenching

Quenching is a process of cooling a metal very quickly. This is most often done to produce a martensite transformation. In ferrous alloys, this will often produce a harder metal, while non-ferrous alloys will usually become softer than normal.

To harden by quenching, a metal (usually steel or cast iron) must be heated above the upper critical temperature and then quickly cooled. Depending on the alloy and other considerations (such as concern for maximum hardness vs. cracking and distortion), cooling may be done with forced air or other gases(such as nitrogen. Liquids may be used, due to their better termal conductivity such as wáter, oil or a polymeterdissolved in water, or a brine Upon being rapidly cooled, a portion of austenite (dependent on alloy composition) will transform to martencite, a hard, brittle crystalline structure. The quenched hardness of a metal depends on its chemical composition and quenching method. Cooling speeds, from fastest to slowest, go from polymer , brine, fresh water, oil, and forced air

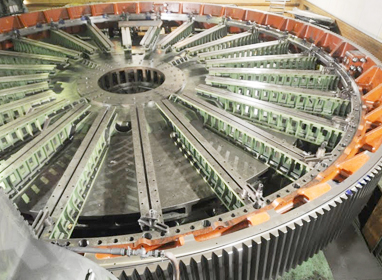

Salt Bath Heat Treatment

Is a heat treatment process comprising an immersion of the treated part into a molten salt.

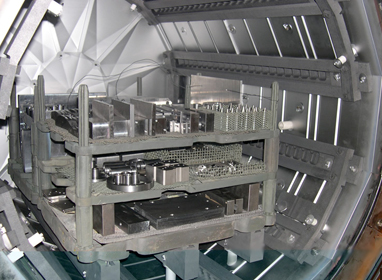

Hi Vacuum Heat Treatment

Vacuum heat treating consists of thermally treating metals in heated enclosures that are evacuated to partial pressures compatible with the specific metals and processes.

Cold and cryogenic treating

Although quenching steel causes the austenite to transform into martensite, all of the austenite usually does not transform.

Nitriding

Nitriding heats the steel part to 482–621 °C (900–1150 °F) in an atmosphere of ammonia gas and dissociated ammonia.

Carburizing

Carburizing is a process used to case harden steel with a carbon content between 0.1 and 0.3 wt% C